Meeting legal requirements isn't just about ticking boxes — it's about ensuring safety and reliability.

At Franklin Equipment, we stress the importance of the mandatory 10-year major inspections for your EWP, a legal necessity that guarantees your equipment adheres to safety standards and regulations. Our expertise ensures not only compliance but also peak performance of your machinery.

Get in touch for a free, no obligation quotation

At Franklin Equipment, we understand that safety is a top priority when it comes to operating EWP Type Access Machinery. That's why we offer comprehensive major inspection services to ensure that your equipment is always in top condition and meets all safety standards.

We have the expertise and experience to undertake all major, annual and 90-day inspections for most types of EWP Access Machinery.

An EWP (Elevated Work Platform) Major Inspection is a comprehensive review and testing of your access equipment, such as boom lifts, scissor lifts, and vertical lifts, after a significant period of use, typically 10 years.

This inspection is crucial to ensure that your equipment is safe, compliant with Australian Standard AS/NZS 1418.10:2011, and operates efficiently. It involves a thorough examination of mechanical, structural, and safety systems.

The main goal of the EWP Major Inspection is to ascertain the safety and operational integrity of your equipment. Given the rigorous nature of the work EWPs perform, components can wear out or become less reliable. This inspection ensures that every part of your EWP is in optimal condition to prevent accidents and ensure compliance with safety regulations.

The process is extensive and includes:

Initial Assessment: Reviewing the equipment's service history and current condition.

Dismantling Critical Components: For detailed inspection of the hydraulic and mechanical systems.

Structural Inspection: Checking for any signs of wear, damage, or corrosion.

Non-Destructive Testing (NDT): Assessing the integrity of welds and steelwork.

Safety Component Inspection: Ensuring parts like emergency descent systems, limit switches, and control systems are functioning correctly.

Load Testing: Verifying the EWP can safely handle its maximum load.

Electrical and Hydraulic System Checks: Ensuring all systems are operational and leak-free.

Functional Testing: Operating the EWP through its full range to identify any operational issues.

Reassembly and Final Testing: Ensuring the equipment is reassembled correctly and operates as expected

After the initial 10-year period, subsequent major inspections are recommended every 5 years. Enhanced periodic inspections should begin after the first 5 years of service and continue every 5 years, ensuring all critical components are inspected by the 10th year.

A competent person or entity, well-versed with the relevant Australian Standards, codes of practice, and legislation, should conduct these inspections. This might be the manufacturer, an engineering tradesperson, or a professional engineer, depending on the complexity of the inspection.

Non-compliance can lead to legal repercussions, including fines, increased insurance premiums, or even litigation in case of accidents. Regular inspections and maintenance can prevent these outcomes and ensure the safety and efficiency of your equipment.

The cost varies based on the type and model of the machinery but generally ranges between 25 to 35% of the original purchase price of the equipment. Note that this cost does not include any potential repairs that might be necessary following the inspection.

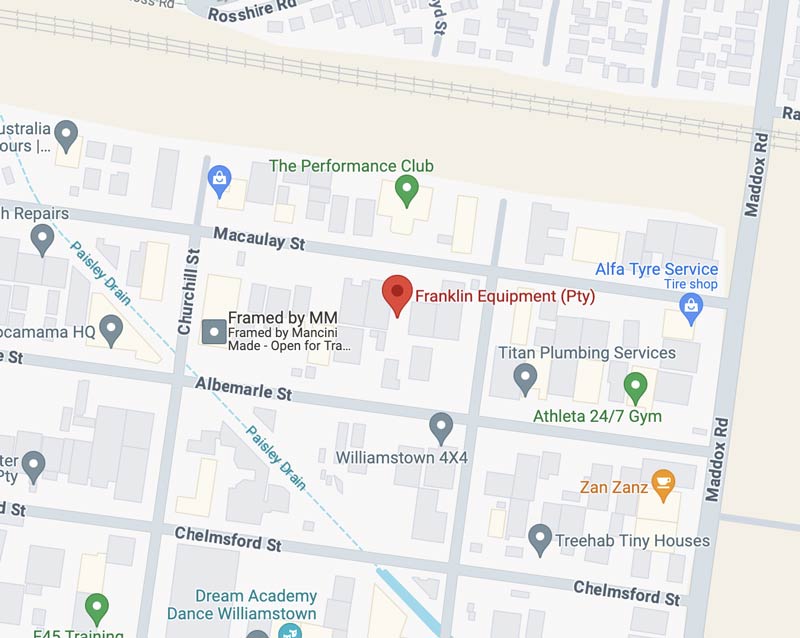

For further information or to schedule your EWP Major Inspection, please contact Franklin Equipment's dedicated service team.